Due to its unique combination of properties, the Sumfoam material class has proven to be a real all-rounder for the most diverse fields of application. In addition to the already established Capsute and Insute product lines, we are constantly working on the development of new Sumfoam products to open up further areas of application - always with a view to acting in the spirit of sustainability and improving applications through the use of our material class.

ADDITIVES

Additives with multiple functions

Sumfoam can be added to products in small quantities to give them certain functional or even optical-decorative properties. In this way, they can be optimized with regard to numerous characteristics such as weight or structure - and all this with just one additive. Grinding to a fine powder while maintaining full performance enables a variety of applications, ranging from paints, lacquers and coatings to adhesives and sealants.

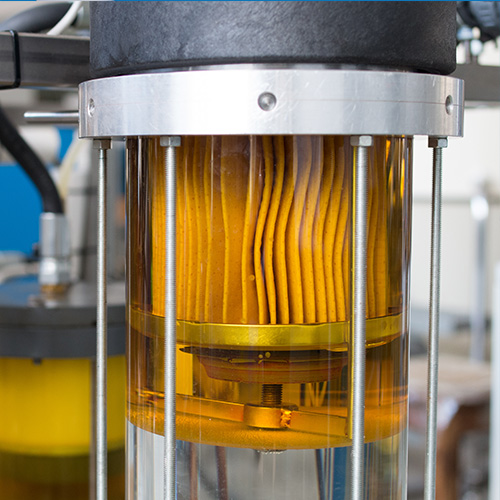

Filtration

Effective treatment of liquids and gases

Whether in the filtration of air, water or oil – the nanoporous structure allows for the removal of the finest particles from the media. Sumfoam offers a good alternative to activated carbon in many applications and can be used, for example, for compressed air de-oiling. The polymer foam is also capable of selectively separating oils from emulsions - a special function suitable for water treatment. Through an additional coating of the inner structure, the foam can be used for a variety of filtration options. Sumfoam can be installed in filter systems in the form of flakes or powder in exchangeable cartridges.

Oil binder

Efficient and permanent binding of pollutants

Due to its open and hydrophobic cell structure as well as its pore size in the nanometer range, Sumfoam is able to quickly and selectively absorb non-polar substances such as oils and prevent them from entering the environment. In doing so, it quickly and powerfully absorbs many times its own weight in oil and permanently binds it due to its strong capillary forces. Sumfoam is therefore suitable as an oil binder for industrial applications and in the event of environmental disasters. In particular, the solid structure ensures that the oil is not only absorbed, but remains bound in the foam even under strong pressure.

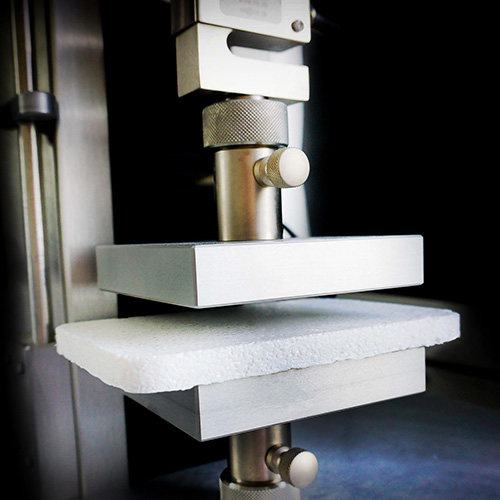

Molded parts

Energy efficiency through insulation panels or molded parts

Within the framework of a two-year research project, we have succeeded in processing our nanoporous foam into molded parts. With their extremely low thermal conductivity, these are convincing both in building insulation and in technical insulation. And our molded parts are also an optimal solution in other areas where high stability, pressure and impact resistance or space and weight savings are required, such as in lightweight construction. Here, the foam can replace solid materials, saving weight and thus CO2 . Due to their high stability, the molded parts are also particularly suitable for shock absorption. In protectors, for example, the forces acting on them are evenly distributed over billions of webs.

Vacuum insulation panels

Vacuum insulation panels

Lighter VIPs improve the CO₂ footprint of transport goods

Highly insulating core material in combination with vacuum: this forms the basis for vacuum insulation panels (VIPs) and thus the best possible insulation. Especially in the transport sector, the focus is increasingly on reducing weight in order to reduce CO₂ emissions.By using Sumfoam as the core material, the weight of the panels is significantly reduced, while maintaining the same performance. The areas of application for VIPs are manifold. They are increasingly used in the healthcare & logistics sector, in the food sector and in the field of home appliances, where the demands on insulation are constantly increasing.

Biopolymers

Sustainable polymers with Sumfoam properties

We are also actively working on another major project, leveraging our unique technology to nanoporously foam renewable biopolymers, achieving the same effect – another step towards a sustainable future.